Cleaning

Cutting

Marking

Welding

Cleaning

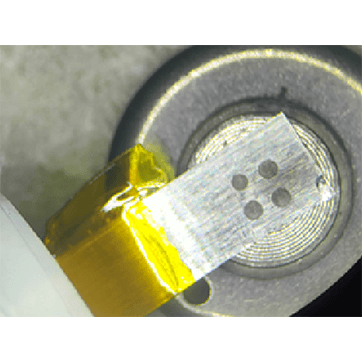

Laser cleaning before pole piece coating can effectively avoid the damage caused by original wet ethanol cleaning; laser cleaning before battery welding uses pulsed laser to make the substrate heat and vibrate to expand, so that pollutants can overcome the surface adsorption force and separate from the substrate to achieve decontamination effect; during the battery assembly process laser cleaning can perform on insulating plates and end plates, clean the surface of the battery cells, roughen the surface of the battery cells, and improve the adhesion of glue or glue.

Laser cleaning technology uses nanosecond or picosecond pulsed laser to irradiate the surface of the workpiece to be cleaned, so that the surface of the workpiece instantly absorbs the focused laser energy, forming a rapidly expanding plasma. It is a cleaning method that effectively removes surface attachments by vaporizing or peeling off oil stains, rust spots, dust residues, coatings, oxide layers or film layers on the surface. GZTECH GMC series adopts laser high-precision cleaning to meet the needs of fast charging and capacity expansion of batteries perfectly realizes the cleaning of positive and negative pole pieces.

Cutting

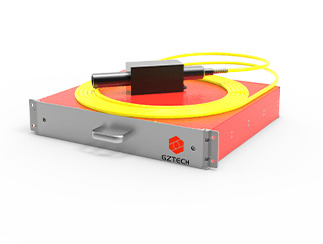

Laser cutting technology can be used in the process of tab cutting and forming, pole piece cutting and diaphragm cutting in the lithium battery manufacturing process. Compared with die cutting, laser cutting has the advantages of higher accuracy and lower operating costs, which helps Improve efficiency and reduce costs in battery production.

Laser tab forming is the current mainstream technology. Process parameters, control system, and cutting station design determine the cutting speed and quality. GZTECH high quality 200W 500W GM SERIES with no burr and no thermal influence, the fastest response time of frequency conversion and power conversion is less than 10μs, which can effectively reduce the quality problems caused by parameter changes at corner joints.

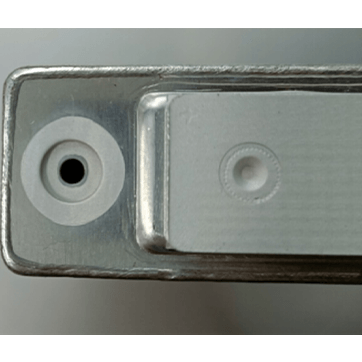

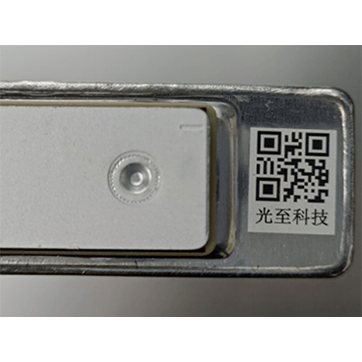

Marking

In order to better control product quality and trace the entire production information of lithium batteries, including raw material information, production process and process, product batch, manufacturer and date, etc., it is necessary to store key information in the QR code and on the battery to identify. The traditional ink jet coding technology has problems such as easy friction and easy loss of information for a long time, while laser marking has the characteristics of strong permanence, high anti-counterfeiting, high precision, strong wear resistance, safety and reliability, and can provide the best solution to track product quality.

Welding

As a modern welding technology, laser welding has the advantages of deep penetration, high speed, small deformation, low requirements for the welding environment, high power density, not affected by magnetic fields, not limited to conductive materials, and does not require vacuum working conditions. The welding process does not produce X-rays and other advantages, and is widely used in high-end precision manufacturing fields, especially in the new energy vehicle and power battery industries. There are many welding parts of power battery, which is difficult and requires high precision. Power battery manufacturers also have high requirements for the automation, safety, precision and processing efficiency of battery production equipment.