Welcome:GZTECH

Welcome:GZTECH

The advantages of MOPA pulsed fiber lasers lie in adjustable parameters, large adjustable range and wide applicable process. The exploration of new processes requires a higher technical level of engineers, and a systematic method is needed to guide them. Starting from the composition of the pulsed laser marking system, this post analyzes the main technical problems in the pulsed laser processing, which is used to guide the process practice.

Taking a typical pulsed laser marking system as an example, it generally consists of 5 main parts.

Commonly used lasers include Q-switched pulsed lasers, MOPA pulsed lasers, ultraviolet solid-state lasers and CO2 gas lasers, etc. According to different materials and processing techniques, select the appropriate laser source. Choose the right laser source for different materials and processing processes. For metal materials, infrared fiber pulsed lasers can meet most needs. For plastics, wood or composite materials, UV or far-infrared CO2 lasers may be more suitable. Actual material properties and processing requirements vary and often require verification of multiple laser sources to select the right type.

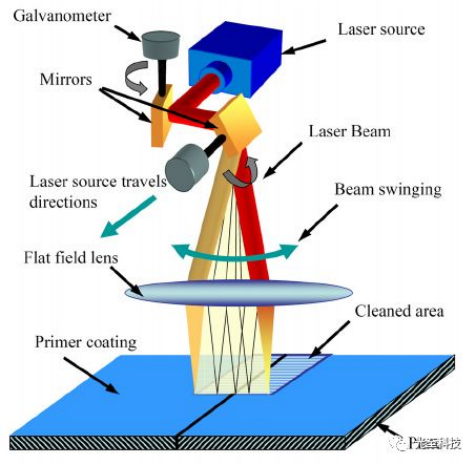

The galvanometer consists of a reflective lens and a rotating motor, and two orthogonal galvanometers are used to achieve two-dimensional plane scanning. The galvanometer lens materials include single crystal silicon, K9 glass and quartz lenses. The surface of the lens is coated with a film that is highly reflective to the laser. The higher the laser power, the higher the requirements for the reflectivity and heat dissipation performance of the lens. The size of the lens needs to match the size of the laser output spot. For example, the diameter of the collimated spot of the commonly used MOPA pulsed laser is about 7mm, and the galvanometer is usually about 12mm. Motor rotation speed and accuracy are very critical for many high-speed and precision marking applications. High-speed galvanometers generally need to use thin and light lenses to reduce inertia, while higher power requires enhanced heat dissipation.

Flat field lens consist of multiple lens groups, focusing collimated beams incident at different angles onto the surface of the material. According to the material, there are ordinary K9 glass field mirrors and fused silica field mirrors. According to the characteristics of the focal plane, there are ordinary field lens and telecentric field lens. For telecentric field lens in the working area, the focal point are in a plane, while the focal plane of ordinary field lens is low in the center and high outside the arc.

The control card and control software are the brains of the laser marking system. The control card responds to the signal of the control software and controls the working parameters and timing of the laser and the galvanometer through the digital signal of the hardware circuit. The control software adopts a graphical interface to edit the shape, size and position of the pattern to be marked, and use an appropriate filling method to process the graphics. In order to adapt to the difference in the control signals of different lasers, the software has built-in options for typical laser types. Most of the domestic control signals are compatible with IPG, and the SPI control signals are relatively independent. The control software generally needs to be installed in a desktop computer or tablet computer to realize human-computer interaction.

All hardware is installed on the machine table. The cantilever is used to install the laser output head and the height is adjustable. And the platform under the field lens is used to fix the workpiece to be processed, and try to keep it horizontally stable. Fiber lasers are generally installed in the bottom body to ensure adequate ventilation and heat dissipation. Power, emergency stop and key switch are installed in prominent locations. As the popularity of laser marking machines gradually penetrates from the traditional industrial market to the consumer-grade market, there is an increasing demand for the miniaturization of marking systems. Through the integrated design and integration of various components, it is now possible to achieve a desktop-level marking system, suitable for office and even home applications.

The following takes the application of MOPA pulsed laser as an example to introduce the selection method and the issues to be noted for the main equipment accessories in general process practice.

The main considerations for laser selection are effect, efficiency and cost performance. The main parameters that affect the process effect of MOPA laser are pulse width, pulse energy and beam quality. When using MOPA laser proofing, the first parameter to be determined is the pulse width. Long pulse has high energy, large heat-affected zone, and rough shading, suitable for simple marking, cutting, deep engraving and other so on. Short pulse has a high peak value, small heat-affected zone, smooth shading, but low energy, suitable for fine surface treatment processes such as blackening, coloring and anode breaking. For applications that require a certain amount of energy and control the scope of the heat-affected zone, you can choose a medium pulse width, such as scribing. Cleaning applications do not have high requirements for laser beam quality. For applications that are sensitive to power density, such as sheet metal welding, it is necessary to ensure excellent beam quality. After confirming the laser parameters required to achieve the effect, the higher the average power of the laser, the faster the processing speed in general, but the price of the laser will be more expensive. It should be pointed out that in some applications, too high average power will also affect the effect of processing, especially with additional thermal effects, which should also be paid attention to during selection.

The following parameters need to be considered when selecting the galvanometer:

The laser wavelength and power determine the material of the lens. Taking the fiber galvanometer as an example, currently the ordinary galvanometer is made of K9, which can withstand MOPA laser power of less than 50W. If the power exceeds 50W, it is recommended to use a galvanometer made of fused silica.

At present, the diameter of the incident diaphragm of most galvanometers is 10mm or 12mm, and the diameter of the incident beam is smaller than the maximum incident spot diameter allowed by the galvanometer. For example, if the diameter of the incident beam is 8mm, you can choose the maximum incident spot of 10mm;

The galvanometer needs to be matched according to the processing effect and speed of the product. Different galvanometer motors can achieve different speeds and response times. It is necessary to select the appropriate galvanometer according to the actual requirements.

The average price and reputation of different galvanometers in the market also correspond to the differences in accuracy, stability and temperature drift characteristics. It is necessary to comprehensively select cost-effective galvanometers according to needs.

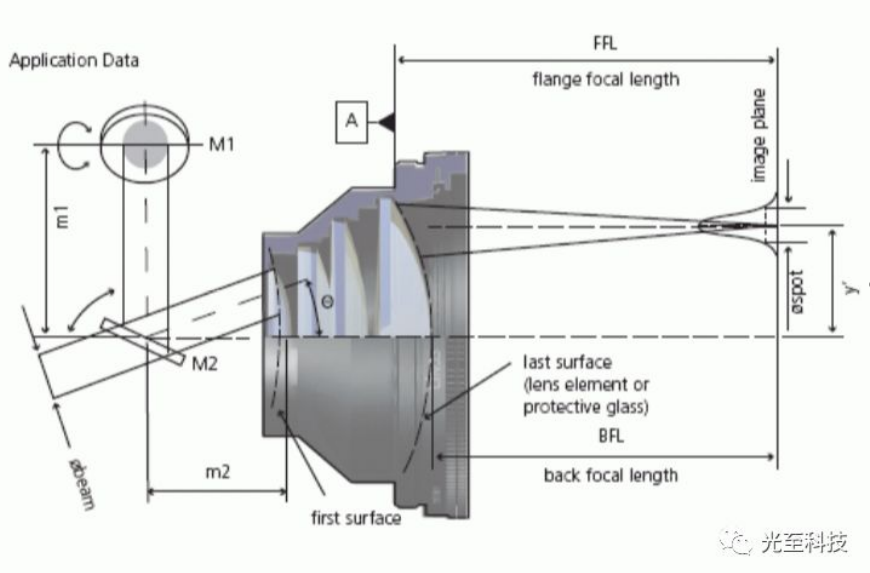

The selection of field lens mainly considers focal length, format, material and configuration. The commonly used focal length is divided into multiple gears from 110mm to 330mm or even larger. The longer the focal length, the larger the laser focal spot. The processing speed is higher, and the field lens with a large focal length corresponds to a larger working area. On the contrary, the short focal length of the field lens corresponds to a small focal spot size and high power density, which is suitable for some fine processing. In particular, it should be noted that the depth of the light spots corresponding to the long focal field lens is also larger, and the short focal point is the opposite. If the surface of the workpiece is undulating or the machining depth is deep, the matching focal depth needs to be considered. If it still cannot be satisfied, consider increasing the movement of the z-axis. In terms of material, the field lens is mainly made of K9 glass or fused silica glass, and it is recommended to use fused silica glass above 50W. If it is necessary to ensure that the laser focus is on a plane on a larger processing width, or to ensure that the difference in the spot size of the processing plane is small, it is recommended to use a telecentric field lens. Compared with ordinary field lenses, telecentric field lenses are larger in size and more expensive.

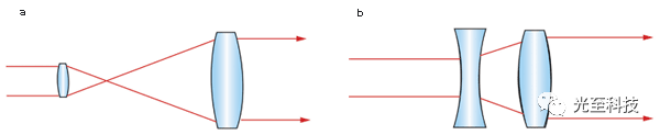

The spot diameter of the conventional MOPA laser is 6mm/7mm. If it is necessary to further reduce the size of the laser focal spot on the surface of the material, an external beam expansion method can be used. On the one hand, the material of the beam expander also needs to be selected according to the average power. On the other hand, because the beam expander is external, it is necessary to adjust the coaxiality of the laser and the divergence angle of the output spot after beam expansion. There are two typical configurations of beam expanders. For the first configuration, the beam expansion ratio is equal to the ratio of the focal lengths of the two lenses.

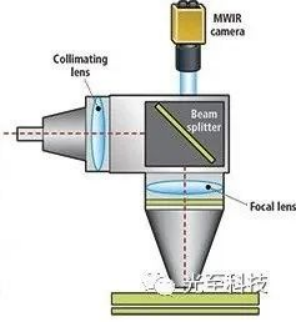

The above two typical beam expander optical path vision, including coaxial vision and paraxial vision, are mainly to ensure accurate positioning during processing. Through a 45-degree beam splitter, the 1064nm laser is highly reflective, and the visible light reflected from the material is highly transparent, as shown in the figure below. In practice, if the beam splitter is poorly coated, or the installation angle deviates from 45 degrees, it may cause a large attenuation of the laser.

Including choosing different filling methods, filling density, filling angle, and multiple filling layers, etc. The specific filling is realized by the control card sending control commands to the laser and the galvanometer. It is necessary to specify the parameters such as the oscillator jump delay and the laser out delay and off delay. Improper filling method settings can sometimes cause periodic streaks in the marked pattern.

When processing some mesh, sheet, lamination or special-shaped materials, it is best to cooperate with appropriate tooling to ensure that the workpieces remain stable or in close contact during the processing.

Protective gas purging is a common means in continuous laser cutting and welding applications, and is less frequently used in pulsed laser processes, but additional gases may be considered in some applications where oxidation of the processed surface is a high requirement.

The standard machine table is only to provide support and level to the hardware and keep it stable. In some occasions where the processing format is large or the position accuracy is extremely high, the working mode of the galvanometer often cannot meet the requirements, and the mode of fixed lens and moving platform needs to be used. The workpiece is fixed on the platform for two-dimensional movement. Through cooperation with the control software, the processing of infinite widths can be realized.

The above is a summary of the factors to be considered in selecting hardware configurations and accessories commonly used in process practice. In practice, the detailed optimization of parameters and the problems that may be encountered are more complicated and require rich experience and careful debugging and analysis. GZTECH fiber lasers are widely used in many industrial processing fields. We have an experienced and professional technical support team. Welcome to call us for inquiries and communications.

By continuing to use the site you agree to our privacy policy Terms and Conditions.