Marking

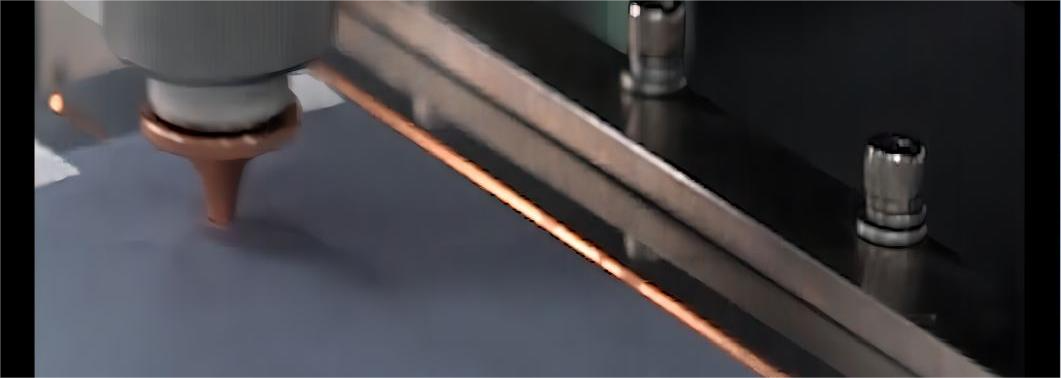

Cutting

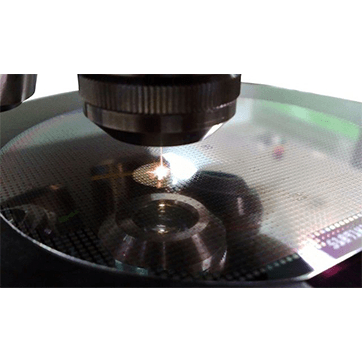

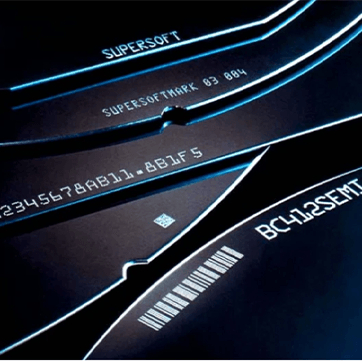

Marking

Laser marking is a marking method that uses a high-energy density laser beam to act on the target to cause physical or chemical changes on the target surface, thereby obtaining a visible pattern. A high-energy laser beam is focused on the surface of the material, causing the material to vaporize rapidly, forming pits.

Cutting

In the process of wafer processing, making a laser identification code at a specific position of the wafer can effectively enhance the traceability of the wafer, and also provide a certain convenience for production management. At present, making laser identification codes on wafers has become a potential industry standard, and is widely used in silicon and germanium materials.