Copyright © 2022 Wuhan Guangzhi Technology Co., Ltd All rights reserved.Site MapDesigned by

Welcome:GZTECH

Welcome:GZTECH

Photovoltaic energy is a clean, safe, and renewable source of energy that has many advantages, such as low carbon emissions, low cost, and wide applicability. On April 23, 2023, the National Energy Administration released statistics on the national power industry for the first quarter of the year. The newly installed photovoltaic capacity was 33.66GW, an increase of 154.81% year-on-year; the newly installed capacity in March was 13.29GW, an increase of 463% year-on-year. In the first quarter, the new investment in photovoltaics was 52.2 billion yuan, a year-on-year increase of 177.6%. As of the end of March, cumulative photovoltaic installed capacity surpassed hydropower to become the second-largest power source in China. As a renewable energy source, photovoltaic energy plays a pivotal role in addressing energy issues. China's solar photovoltaic industry has become one of the fastest-growing emerging industries globally.

The most important aspect of photovoltaic production is cell manufacturing. In addition to the mainstream PERC technology for solar cells, new technologies with greater efficiency potential, such as TOPCon, HJT, and XBC, have emerged. Laser technology is an effective technique for reducing costs and increasing efficiency in photovoltaic cell production. Laser technology has numerous applications in photovoltaic product manufacturing, such as laser scribing for thin-film cells, film opening, doping, laser cutting, laser drilling, and laser edging for crystalline silicon cells. With its precise patterned local processing and rapid cutting ability, laser processing has become an essential way to improve solar cell conversion efficiency.

GZTECH provides a detailed introduction to various applications of laser processing technology in photovoltaic production. Let's take a look.

Using lasers to scribe and cut silicon wafers is currently considered the most advanced method due to its high precision, high repeatability, stable performance, fast speed, simple operation, and easy maintenance.

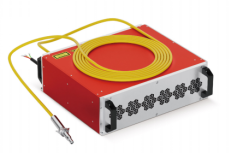

Recommended model one: Non-destructive pulse YFPN-50-GLE+ continuous air-cooled single-mode fiber laser 300W.

The GLE pulse series from GZTECH has extremely high cost-effectiveness and stability. The CW series laser adopts a air-cooling heat dissipation design with a compact structure. Through reasonable optimized design on the optical path, the laser output beam quality is very close to the diffraction limit, which can achieve higher processing accuracy. It has features such as high beam quality, fast response time, high reliability, and high modulation frequency and so on.

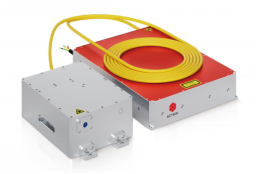

Recommended model two: Silicon wafer cutting quasi-continuous wave (QCW) or continuous single-mode fiber laser 300W.

GZTECH's air-cooled QCW series laser uses air-cooled heat dissipation and shelf-type chassis design. It features 10 times power modulation, with options for single-mode and multi-mode capabilities. With high electro-optical conversion efficiency, low energy consumption, no need for adjustment or maintenance, flexible fiber optic output, and easy portability, this laser stands out from the competition.

Using MOPA fiber pulsed lasers with high peak values can quickly drill holes in photovoltaic glass and prevent excessive power loss. Dual-stage isolators effectively protect photovoltaic glass from reflection damage. Energy losses caused by solar cell leakage currents are greatly reduced, from 10-15% with traditional chemical processes to only 2-3% with laser technology.

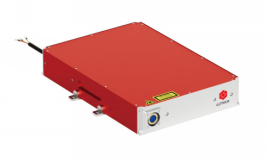

Recommended model: GT series pulsed fiber laser integrated machine 80W, 120W.

GZTECH's GT series laser adopts the MOPA structure with master oscillator power amplification, which focuses on optimizing both the pulse peak power and beam quality. This design allows for maintaining high beam quality under high-power working conditions, with a maximum peak power exceeding 80KW. The laser has the characteristics of small pulse width, high peak value and high power. It supports independent adjustment of pulse width and frequency, making it suitable for materials applications that demand high peak power and brightness, particularly in precision processing.

Laser melting (laser grooving) technology is used to etch the passivation layer of solar cells, realizing efficient and high-quality production of PERC cells and becoming a core equipment for upgrading traditional cell technology to industrialization. Selective doping is done on the surface of the cell to form a heavily doped area to reduce resistance, combined with light-doped emission structures in front-end processes and grid electrodes formed by electroplating or screen printing in back-end processes to improve cell efficiency.

Recommended model: Fiber green laser 60W.

GZTECH's high-power fiber green laser uses a fiber fundamental frequency amplification and external cavity doubling technology route, with technical advantages such as high average power and adjustable first pulse. The optimized single-mode amplification technology scheme can achieve high beam quality green light output. Through MOP optical scheme, the pulse number and frequency can be adjusted, and the long pulse width version can achieve higher pulse energy output.

GZTECH's laser processing technology plays a crucial role in reducing costs and increasing efficiency in photovoltaic production. Through its advanced laser equipment and specialized knowledge, GZTECH empowers the photovoltaic industry to meet the increasing demand for renewable energy and contribute to a greener future.

By continuing to use the site you agree to our privacy policy Terms and Conditions.