Copyright © 2022 Wuhan Guangzhi Technology Co., Ltd All rights reserved.Site MapDesigned by

Welcome:GZTECH

Welcome:GZTECH

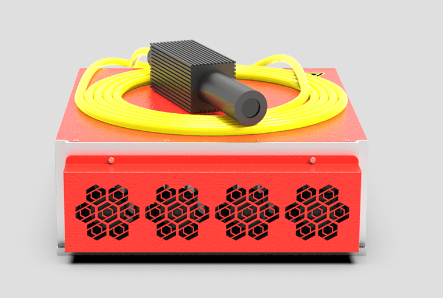

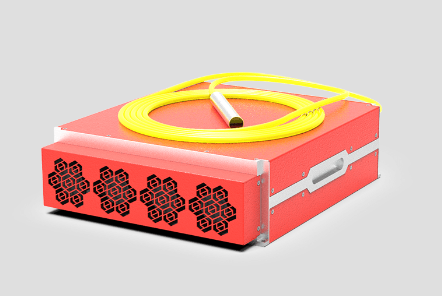

The Master Oscillator Power Amplifier (MOPA) refers to a system that is made up of a 'master' laser and a few stages of optical amplifier to boost the output power. Alternatively, conventional fiber lasers are powered using Q-Switch technology, which creates laser pulses that last mere billionths of a second. Thus, because the energy from the laser is emitted in such a brief period, the energy is concentrated into very powerful pulses. A MOPA laser can generate a higher pulse repetition rate than its Q-Switch-powered counterparts. Furthermore, the pulse frequency range of a MOPA laser is much larger than that of a Q-Switch laser.

The light of marking lasers is generated in pulses. Generally, the pulse duration is non-adjustable. What is special about a MOPA laser is that its pulse duration is variable: Long or short pulses can be adjusted in steps between 2 and 500 ns.

Additionally, the laser parameters pulse duration, pulse frequency and pulse energy can be adjusted nearly independently of one another which results in a high flexibility.

Furthermore, there is a difference regarding the pulse frequency itself: While the range of the pulse frequency of a so-called standard laser lies between 30kHz and 120 kHz, it lies between 1 kHz and 4 MHz for a MOPA laser.

In summary, the MOPA laser offers more flexibility regarding the adjustment of laser parameters. Thus, the MOPA laser is extremely versatile and can be adapted to the material very accurately if needed.

Compared with Q-switched fiber lasers, MOPA pulsed fiber lasers can be used in almost all applications in the marking field. The Q-switched laser is subject to its principle and cannot adjust the pulse width parameters, so it is difficult to achieve fine marking.

The MOPA laser can flexibly adjust the pulse width, frequency parameters, pulse width and repetition frequency, and the single-pulse energy is easy to control.

For applications such as the blackening of anodized aluminum and coloring of stainless steel, the MOPA pulsed fiber laser has a high peak power, which can achieve the effect that the Q-switched laser cannot achieve.

With the portable and thinning of digital products, the casing is made thinner and thinner. When using a laser to remove the paint layer, it is easy to cause deformation of the backside, and a "convex hull" is generated on the backside, which affects the aesthetics of the appearance. Using the parameters of the MOPA laser with a smaller pulse width makes the laser stay in the material shorter. On the premise that the paint layer can be removed, the speed is increased, the heat residue is less, and it is not easy to form a "convex hull". Therefore, MOPA pulsed fiber laser is a better choice for the surface cleaning of alumina sheets.

GZTECH was founded on May 31st, 2018. GZTECH’s market strategy is to become a leading supplier of advanced industrial laser products for precision manufacturing. We have a first-class research and development team which consists of optics, electronics, software and mechanics engineers. We can provide fiber laser products operating on 1064nm, 1550nm 1940nm and 355nm wavelength ranges, and green lasers based on extra-cavity second-harmonic generation technology. For more information about MOPA Laser, please kindly contact us immediately.

By continuing to use the site you agree to our privacy policy Terms and Conditions.