Copyright © 2022 Wuhan Guangzhi Technology Co., Ltd All rights reserved.Site MapDesigned by

Welcome:GZTECH

Welcome:GZTECH

In the industry, MOPA laser is an agreed common name for a nanosecond pulsed fiber laser based on electrically modulated seed source plus multi-stage power amplifier, mainly used for laser marking and precision cutting, welding, drilling and so on. The representative manufacturer is SPI. Physically, MOPA is a laser configuration relative to the single oscillator configuration. The full English name is Main Oscillator and Power Amplifier. And it is not a specific laser type.

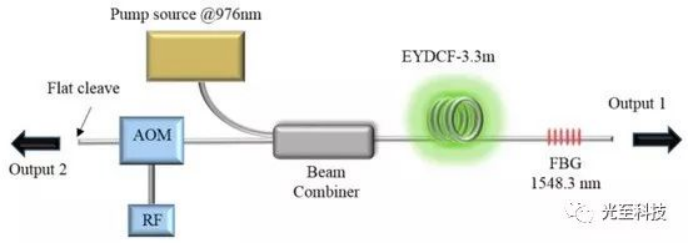

A Q-switched laser is to insert a Q switch into the CW laser. The so-called Q value can be simply understood as the loss of laser transmission in the oscillator. For example, the Q-switched laser, which ranks first in terms of sales volume among fiber lasers, is a fiber acousto-optic modulator (AOM) inserted in the continuous oscillator cavity, and obtains a laser signal with a specific repetition frequency and pulse width by controlling the periodic switching of the AOM. When the AOM is turned off, the gain fiber in the cavity stores energy under the pump excitation. When the AOM is turned on, the signal pulse is generated and reflected and enhanced many times in the cavity, and finally a strong laser pulse output is formed, similar to the water storage and flood discharge of a dam. The typical operating pulse width of a Q-switched fiber laser is in the range of tens to hundreds of nanoseconds and cannot be actively adjusted due to the operating bandwidth and re-frequency of the AOM itself, while the pulse re-frequency is in the range of 10 kHz to 100 kHz.

Compared with Q-switched lasers, MOPA lasers have a lot of room for adjustment in terms of pulse width, pulse frequency, and regulation waveform, so the combination of various parameters can be used to make the required adjustment for different materials during debugging. If users need specific models, they can also modulate exclusive laser parameters to provide users with a full range of laser application solutions. The output waveform can be flexibly controlled by modulating the seed signal source, with a pulse width adjustment range of 2ns-500ns, and a wider frequency adjustment range of 1-4000kHz. The output pulse width of the Q-switched fiber laser is not adjustable, and the pulse width is generally unchanged at a fixed value of 80ns-140ns.

For application difference, MOPA laser has obvious advantages in the following application.

Anodized materials are removed from the surface oxide film by laser to achieve conductive or marking functions, such as marking conductive bits of metal shell 3C products and logo marking.

Use the laser to remove the plating layer of the material without damaging the bottom layer to achieve the purpose of isolation or anti-reflection, such as ITO plating removal, automotive glass protection film removal, cell phone cover film removal, etc.

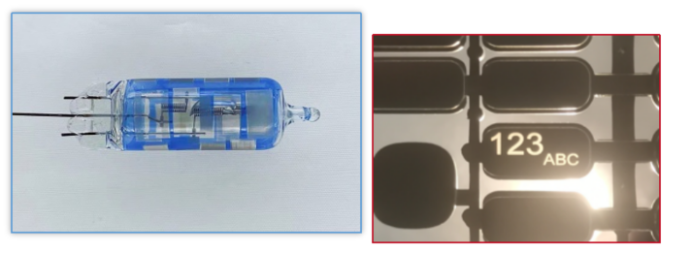

Use laser to remove different layers of paint to achieve layered removal or even complete removal, such as the removal of paint from plastic buttons or resin buttons.

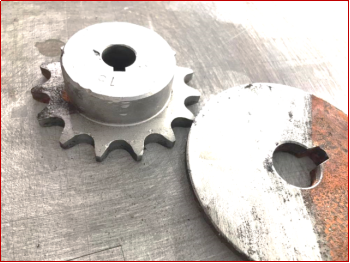

Use lasers to remove contaminants from material surfaces, and remove rust, and deburr, for industrial machine tools, abrasive knives, etc.

Use laser to mark information of text or LOGO on polymer materials, such as wires, bottle caps, 3C electronic product marking, etc.

Use laser to fill and mark stainless steel or metal plating with high density, and form a dense film layer on the surface to reflect different colors.

Mark LOGO and text and other information on the alumina shell.

Carve out the required logo pattern on the specified material to facilitate the next process of surface plating or filling.

Marking text information on the metal material for distinguishing identification, etc.

Use laser with control system to do 3D model marking.

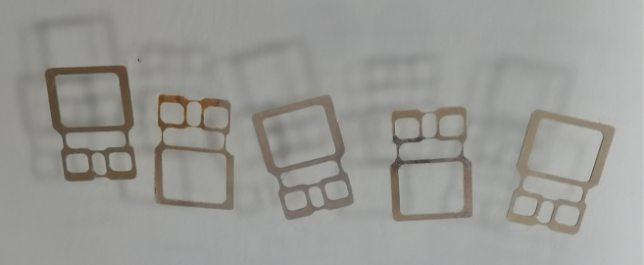

Use lasers to cut metal thin films, such as copper films, and aluminum films in new energy batteries (film thickness less than 100 μm).

Scribing and cutting of metal plates, silicon wafers and other materials

The thin sheet material is welded to the specified base metal by laser to achieve functions such as fixation or conduction.

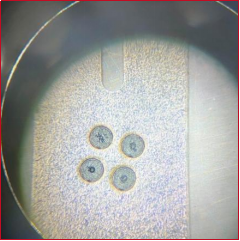

Use laser drilling on the specified materials, such as metal earphones or metal speakers.

Drill holes on copper film, aluminum film, etc.

In the comparison presented above, it can be seen that MOPA lasers can replace Q-switched lasers in many applications. In some of the more high-end applications, MOPA lasers are much even better than Q-switched lasers.

Wuhan Guangzhi Technology Co., Ltd. (hereafter referred as GZTECH for short) was founded on May 31st 2018. GZTECH’s market strategy is to become a leading supplier of advanced industrial laser products for precision manufacturing.

We have a first-class research and development team which consists of optics, electronics, software and mechanics engineers. It can provide fiber laser products operating on 1064nm, 1550nm 1940nm and 355nm wavelength range, and green laser based on extra-cavity second-harmonic generation technology.

For more information about MOPA lasers, please kindly contact us directly.

By continuing to use the site you agree to our privacy policy Terms and Conditions.