Copyright © 2022 Wuhan Guangzhi Technology Co., Ltd All rights reserved.Site MapDesigned by

Welcome:GZTECH

Welcome:GZTECH

Deep laser engraving is a common laser processing application. Compared with traditional methods, deep laser engraving has the advantages of no pollution, high precision, flexible engraving content, and can meet complex engraving processes. In recent years, our country pays more and more attention to environmental protection, and the traditional corrosion process will be gradually replaced. So the market prospect of deep laser engraving is very broad.

At present, deep laser engraving is mainly used in mold engraving, wheel engraving, car VIN code, embossed artwork, steel logos, gas tank logos, jewelry and so on. The engraving materials include carbon steel, stainless steel, aluminum, copper, high-strength steel, etc. What are the factors that affect the depth of deep laser engraving and the roughness of the underlying pattern? It mainly includes laser power, beams quality, pulse width, light emit frequency, filling density, and processing speed, etc. This post mainly studies the effect of pulse width on deep laser engraving.

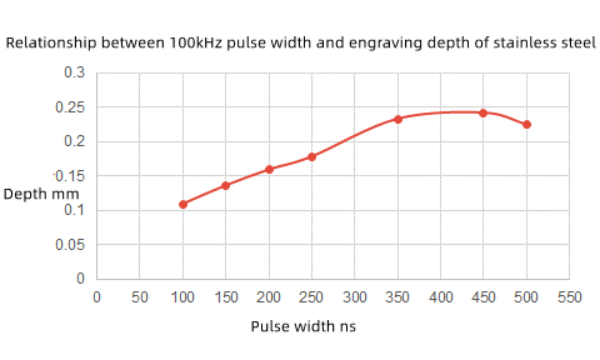

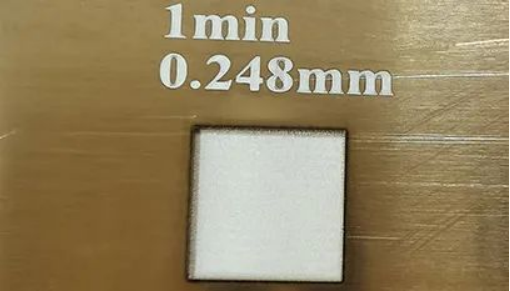

Take stainless steel as an example to test the influence of pulse width on deep laser engraving. When other parameters are fixed, the pulse width increases and the deep laser engraving depth also increases. When the pulse width reaches 350ns, the engraving depth is the largest. This is because when the pulse width is increased, and under the premise of ensuring the damage threshold of the peak damage material, the pulse action time is long and the removal efficiency is high, but the quality of the underlying pattern may not be guaranteed.

Testing lasers on the market

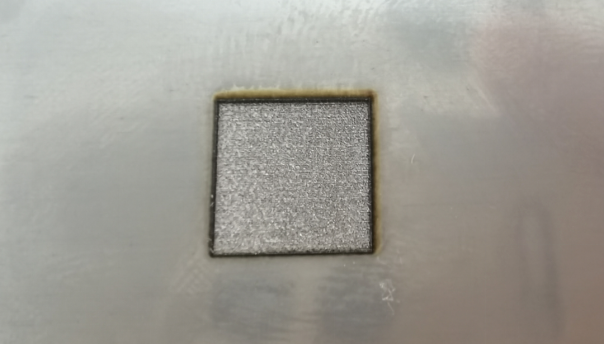

Large pulse width, high efficiency, rough shading

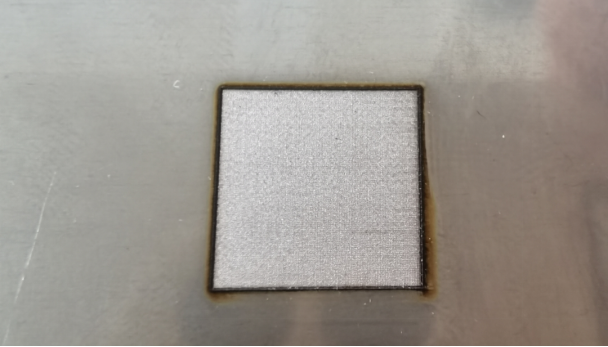

Small pulse width, low efficiency, fine shading

Through the above data analysis, it is concluded that different pulse widths have different effects on deep laser engraving. In practical applications, it is necessary to select appropriate parameters according to the needs of deep laser engraving and take into account the deep engraving efficiency and effect.

In response to the diversification of engraving needs in the market, GZTECH has launched the YFPN-100-GL MOPA pulsed laser through special pulse modulation methods, repeated tests and parameter optimization. It has an adjustable pulse width of 150ns~300ns, which is a significant advantage in deep laser engraving.

Maximum single pulse energy (mJ):1.5

High stability: 24h power fluctuation <3%

Adjustable pulse frequency (kHz):1-1000

Pulse width (ns): 150-350

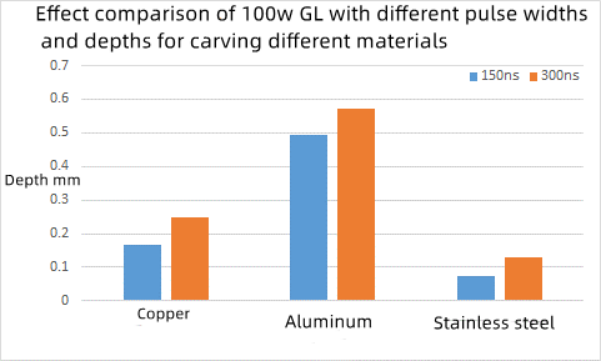

GZTECH’s engineers used GL-100W laser to test the influence of pulse waveform on deep engraving for three different metal materials: stainless steel, brass and aluminum. The test results are as follows.

From the figure, it can be concluded that the pulse width increases, the engraving depth increases, and the shading effect is consistent. In addition, different material properties have different effects on deep engraving. Aluminum has the lowest melting point, so the deep engraving efficiency is the fastest under the same conditions.

Aluminum deep engraving

Copper deep engraving

Stainless steel deep engraving

The current market demand for diversified engraving, and the hardware industry pursue the depth of engraving, and the electronic and precious metal industries focus on fine shading. The parameters of the YFPN-100-GL MOPA pulsed laser of GZTECH are adjustable, which can meet the engraving efficiency and ensure the fineness of the shading. In the highly competitive engraving market, GZTECH will continue to upgrade its products to provide more choices for users.

By continuing to use the site you agree to our privacy policy Terms and Conditions.