Copyright © 2022 Wuhan Guangzhi Technology Co., Ltd All rights reserved.Site MapDesigned by

Welcome:GZTECH

Welcome:GZTECH

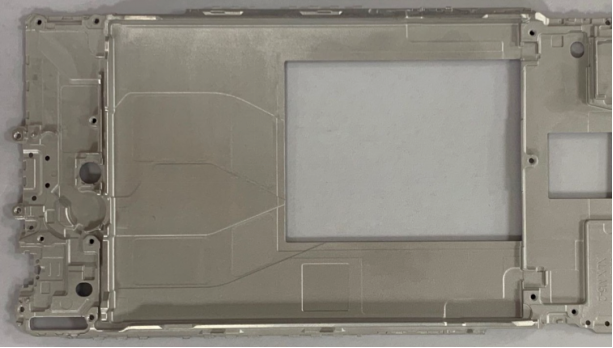

Aluminum-magnesium alloy has many advantages such as low density, high strength, easy forming, and low manufacturing cost, and is widely used in the skeleton of 3C products. For example, a lot of conductive potentials are required on the middle frame of a mobile phone, and its resistance value is required to be less than 0.5Ω to enter the next process. However, magnesium and aluminum in magnesium-aluminum alloys are active elements, which are very easy to react with oxygen in the air to form oxides. The untreated conductive potential resistance can be as high as 8Ω, which cannot meet the requirements of the circuit resistance value in the communication field. Therefore, the conductive potential needs to be processed before entering the next process.

The middle frame of the mobile phone before processing

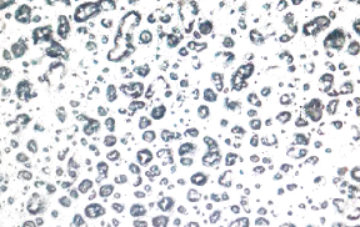

There are many methods of conducting potential treatment. In the early stage, they were made by mechanical methods, but the process was complicated and the yield was not high. Laser processing has the characteristics of non-contact, simple and flexible operation and processing without consumables. This process technology uses focused high-energy-density laser scanning to illuminate the conductive potential area, directly vaporizes the oxide layer on the surface of the laser-irradiated material, and exposes the internal metal material to achieve the goal of improving conductivity. The laser energy given by this method is relatively consistent, but the conductive performance is inconsistent due to the uneven surface material, and the yield is generally only 75-85%, mainly because the early laser generally only has a pulse waveform, and there are not many adjustable laser parameters, and the laser process is simple and difficult to achieve the best effect.

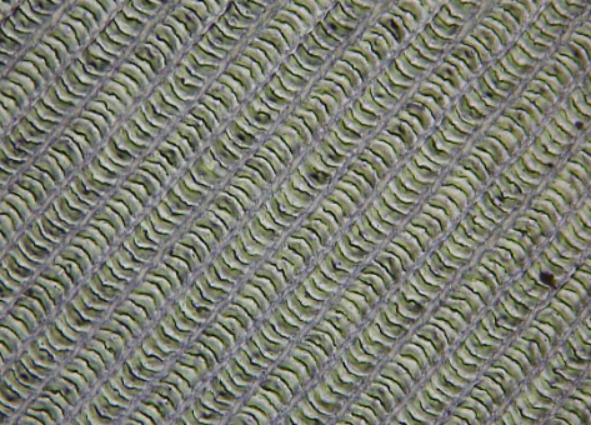

Amplification effect for conventional conduction potential

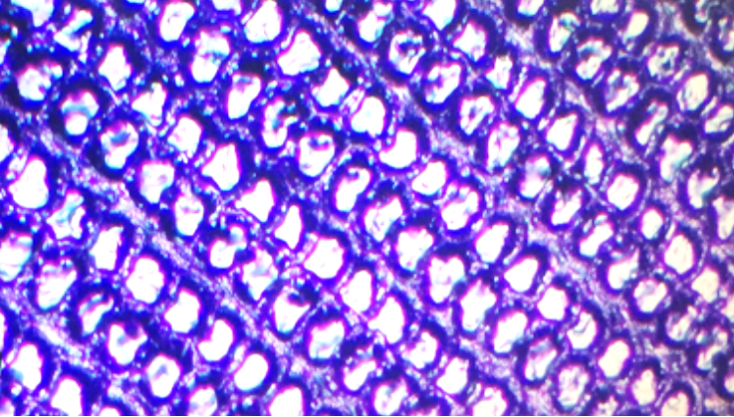

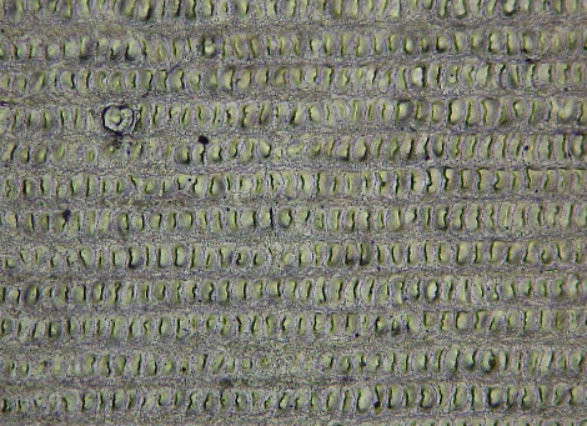

In order to solve the problems of current technology, a method of making fish scale patterns on the surface of aluminum and magnesium alloys was applied. This process uses a multi-waveform adjustable pulse width laser to generate a fish scale conductive potential on the surface of the material by combining multiple layers of parameters. The fish scale pattern conductive potential strips off the oxide layer and at the same time the underlying pattern shows fish scale grid, which has the advantages of clear lines, bright white board surface, not easy to oxidize, and good conductivity. It is also a relatively advanced mobile phone conductive potential technology at present.

Amplification effect for fish scale conduction potential

According to the production process of fish scale pattern conductive potential, GZTECH has launched a cost-effective YFPN-60-GL MOPA laser for the production of fish scale patterns after R&D and testing. The laser has high beam quality and an adjustable pulse width range of 150~300ns.

Maximum single pulse energy (mJ)

1.5

High stability

24h power fluctuation <3%

Adjustable pulse frequency (kHz)

1-1000

Pulse width (ns)

150-300

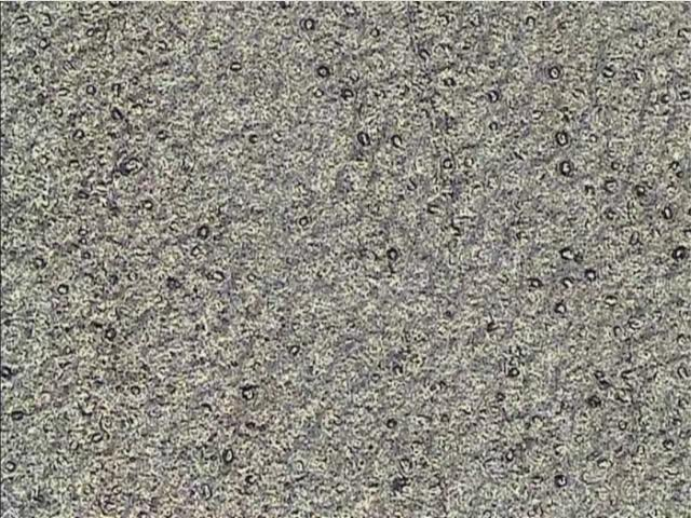

The engineer used YFPN-60-GL and F254 field lens to test the fish scale pattern on the magnesium and aluminum alloy middle frame as follows.

Moderately dense fish scales

Excessive energy effect

After testing, the difficulty of this process is that it requires a large pulse width, high frequency, and slow speed to produce a shiny dense alloy layer on the surface of aluminum and magnesium alloy materials, and then match a certain overlapping method of light spots to make a regular fish scale appearance. For more process inquiries, please contact GZTECH engineers.

By continuing to use the site you agree to our privacy policy Terms and Conditions.