Copyright © 2022 Wuhan Guangzhi Technology Co., Ltd All rights reserved.Site MapDesigned by

Welcome:GZTECH

Welcome:GZTECH

GZTECH aims to be a leading supplier of advanced lasers for precision manufacturing . Since its establishment in 2018, it has continued to upgrade and expand its production system and organizational system. According to the five-step strategy of "products, projects, industries, brands, and platforms", the company's business development has been steadily promoted. At present, the overall layout of Wuhan R&D and production headquarters and three major domestic sales and service centers in Shenzhen, Suzhou, and Jinan have been formed. And the foreign trade sales team and platform have initially taken shape. It has become a laser manufacturer with a scale and brand influence in the laser industry.

The year 2022 is the 4th year of GZTECH's establishment and it is also a year when China's manufacturing industry, including the industrial laser industry, has been plagued by COVID-19. What breakthroughs has GZTECH made in terms of product technology and company development? What is the outlook for the laser industry and the company's future development? With these curiosities, we interviewed Dr. Huang Zhihua, co-founder of GZTECH again.

Dr. Huang said: "In the next ten years, we will continue to pay attention to the new energy market represented by lithium batteries, photovoltaics, and hydrogen fuels, and vigorously expand the market of laser cleaning and hard and brittle material processing." Energy consumption is a direct indicator of the degree of industrial civilization development and the basic driving force for social and economic operations. The replacement of traditional energy with new energy will be an irreversible long-term process. New materials, new technologies and new products will continue to be produced during the development of the new energy industry. The processing of these materials, the upgrading of technology and the manufacturing process of products will create greater demand for lasers of high precision and automation.

Laser equipment in the lithium battery industry as a whole is relatively mature and scaled. The fiber MOPA pulsed high-power laser of GZTECH is mainly used for efficient lug cutting, pole piece cleaning, liquid injection hole, and pole cleaning. In addition, GZTECH's 500W high-power MOPA pulsed laser has also made significant breakthroughs and completed batch deliveries in applications such as battery module welding and disassembly for recycling and enamel wire cleaning for hairpin motors. Anode-free pure aluminum black special picosecond MOPA laser is also a featured product developed by GZTECH, and is expected to become the standard configuration of lithium battery production lines in the future. Dr. Huang believes: "The localized replacement of the core component lasers in the laser equipment of the lithium battery industry has not yet been rolled out on a large scale. We look forward to ushering in a wave of large-scale replacement of localized lasers in 2023."

The market share of laser equipment in the photovoltaic industry is relatively concentrated, new material systems and new process routes are still undergoing rapid iterative changes, and the demand for laser sources is also constantly changing. In addition to MOPA pulses and air-cooled single-mode continuous applications for marking photovoltaic panels, GZTECH's GT line of products has also achieved performance upgrades and head customer volume deliveries in photovoltaic glass perforating applications said Dr. Huang. In addition to infrared lasers, the photovoltaic industry uses a large number of nanosecond and picosecond green laser products. Based on the polarization-maintaining infrared MOPA laser plus extra-cavity frequency doubling technology, GZTECH has developed a 1ns narrow pulse width and 40ns long pulse width of 10W~80W green laser products.

In the field of hydrogen fuel cells, laser processing has not yet formed a scale, and is still in the exploration stage. GZTECH continues to pay attention to the processing technology of hydrogen fuel-related materials and products and provides customers with customized product services. It has achieved good results and efficiency in the processing and verification of several new materials this year. It is expected to usher in small-batch delivery next year.

Dr. Huang also mentioned that laser cleaning is an important occasion for the application of high-power pulsed lasers, and there are prospects for large-scale applications in industries such as rail transportation, precision molds, and marine and automotive. GZTECH has specially developed GMC series products with a power range from 100W to 1000W, including single-mode, few-mode, and multi-mode, with different energy densities, cable lengths, and spot diameters available, and provides customers with highly integrated OEM solutions. With the expansion of the laser cleaning market and the continuous reduction of costs, especially the increase in the cost performance of the high-power segment, the laser cleaning industry will usher in a mid-term economic growth stage.

Processing of hard and brittle materials has always been one of the key application industries of GZTECH. Dr. Huang mentioned that GZTECH's MOPA laser products above 200W have been delivered on a large scale to many leading equipment manufacturers in domestic sub-sectors. Relying on high-performance and high-quality products, GZTECH has made breakthroughs with customers in fine processing processes such as diamond drawing die punching, 3D reduction, and tool head 5-axis machining. The high-pulse energy laser customized by GZTECH for diamond cutting in the Indian market has also been highly praised by customers and is expected to be delivered on a large scale.

Talking about the positioning of product technology R&D in an enterprise, Dr. Huang said: “For technology-based enterprises, product R&D is the eternal power and valuable source of enterprise development.” In 2022, GZTECH has mainly made three major breakthroughs in product technology. One is the fiber pulse amplification technology with large average power and high peak value; the other is high-power and high-efficiency nonlinear double frequency technology; the third is solid cavity type and production technology with high reliability and long life in high-power ultraviolet lasers.

In 2022, GZTECH initially completed the product layout of nanosecond pulsed lasers in three wavelengths: infrared, green and UV. For infrared products, 750W and 1000W MOPA nanosecond pulse lasers have been launched this year; for green laser products, breakthroughs have been made in 80W short-pulse width and long-pulse-width fiber green laser products this year; for UV products, nanosecond high-power solid-state UV lasers from 5W to 30W have achieved product finalization and mass production delivery.

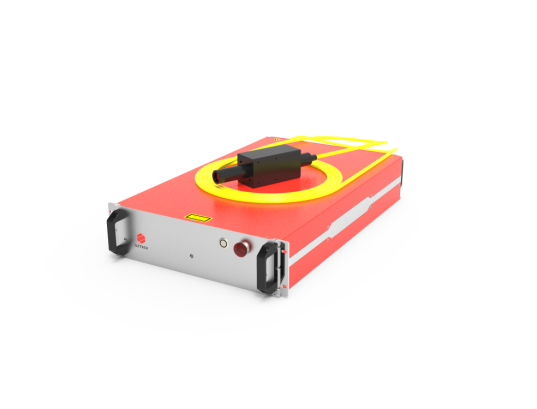

1000W single-mode MOPA pulsed laser

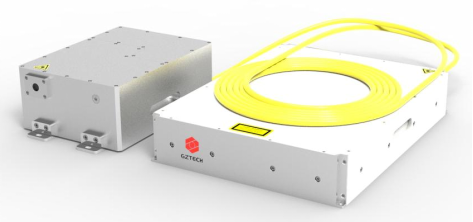

80W fiber green pulse laser

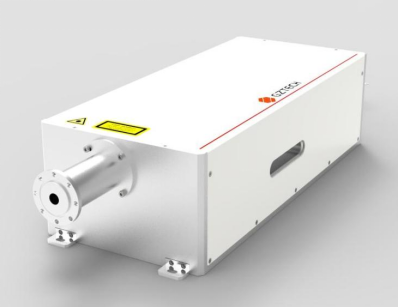

30W solid-state UV pulse laser

Infrared lasers are mainly used for processing metal materials. Green lasers are mainly used for processing semiconductor materials such as glass and photovoltaics. And UV lasers are widely used for processing plastics and composite materials. A richer product range enables GZTECH to better serve customers in the precision processing industry. In Dr. Huang's plan, GZTECH will gradually open up infrared, green, and UV laser products under various pulse working systems of nanoseconds, picoseconds, and femtoseconds in the next three years, providing customers with more abundant laser processing solutions.

In addition to industrial products, GZTECH also cooperates with well-known domestic universities and research institutes to carry out research and development of cutting-edge laser sources. The 266nm deep ultraviolet picosecond frequency-locked laser has achieved femtosecond-level time jitter. As a photocathode excitation source, combined with electron acceleration and free electron laser systems, the world's leading high-resolution CT detection experiment has been completed at the Chinese Institute of Physics and Technology. GZTECH has also delivered 1535nm high-power laser systems to Tsinghua University in batches, contributing to the research of advanced high-power fiber lasers. The delivery of scientific research-grade products is a demonstration of the company's R&D capabilities, and it is also an important step for the company to develop advanced laser source systems.

In 2022,GZTECH has initially completed the market layout with Wuhan as the production and R&D center, and Shenzhen, Suzhou, and Jinan as the regional sales and service centers in South China, East China, and North China. Thanks to the multi-point layout, although various places have been affected by the epidemic situation, in turn, this year, GZTECH has always been able to ensure stable operation and minimize the negative impact. "This year, we have achieved about 80 percent of the target set at the beginning of the year, and achieved high-speed business growth despite the unfavorable situation of the pandemic," said Dr. Huang.

In terms of market development and new product development, GZTECH has its own advantages. In terms of the team, the company has a young team mainly born in the 1980s and 1990s, which makes the company more sensitive and responsive to new applications. In addition to common industrial laser applications, the laser industry has many new applications to be developed. In the past 20 years, industrial lasers first flourished in the sheet metal cutting and marking market, then developed in the 3C electronics industry, and recently ushered in the rapid rise of the new energy industry. Each era has new hot industries and new demands for laser products. Dr. Huang believes that laser companies should take the initiative to meet the changes of the times, actively embrace new industries and new applications, strive to develop new products, and expand incremental markets.

In addition to domestic business, GZTECH started to expand foreign trade business at the end of 2021. The company has set up a foreign trade team, set up the Alibaba International website, Google English official website, LinkedIn official account, etc., and fully launched the foreign trade promotion work. Dr. Huang introduced: "After a year of hard work, our company has made some breakthroughs in the foreign trade market. We have already had some customers in India, Brazil, Mexico, and Europe, and the customers are very satisfied with the products. With the re-integration of the global manufacturing supply chain, the overseas market will become an important market segment for the laser industry in the future.”

"Primary school graduation" is Dr. Huang's summary of the current status of GZTECH. In the next stage, GZTECH will focus on completing the categories of industrial laser products, expanding customer groups and application industries, and strengthening brand recognition and market position. "In the long run, if an enterprise wants to survive in the market for 20-30 years, it must devote itself to finding new product directions and new application areas beyond the existing products."

In recent years, China's laser industry has developed rapidly, gradually realizing the independent research and development of some core technologies and devices. When it comes to the differences between domestic and foreign laser enterprises, Dr. Huang said: First, there is still a gap in technology. For example, Trump’s disc lasers may not have matching products in China at present; This old brand laser company has a deep accumulation in technology and products; IPG has a complete layout in the field of fiber lasers.

The second is the gap in the application. Dr. Huang said that many applications were first developed in foreign countries, and foreign companies were able to get in touch with the most advanced applications at the earliest, and at the same time improve product performance according to product needs. For example, foreign companies entered the lithium battery industry relatively early, so it has become the standard in some industries, so domestic companies need to carry out the process of "import substitution". In terms of becoming an industry standard, the current influence of domestic enterprises needs to be improved.

The third is the low-price competition of inferior products. "Better, faster, and more economically" is the highest goal pursued by large-scale manufacturing enterprises. If a company can achieve cheap products with the best performance and occupy the largest market share, and quickly respond to market changes, then such a company is invincible. But in fact, due to fierce market competition, many companies have given up the performance requirements and quality control of products in pursuit of price advantages. We can also hear complaints from customers about the quality and performance of some domestic products.

Of course, in addition to the gap, Chinese laser companies also have their own advantages. First, in the face of the vast local market, they can provide more efficient and convenient localized services; second, in recent years, the technology research and development capabilities of domestic enterprises have improved rapidly, and they can propose their own solutions for precision processing products; third, they have advantages in the cost performance of products, and the iterative upgrade speed is fast. Dr. Huang believes that domestic companies still need 5-10 years to make up for these gaps, and finally, strive to surpass foreign counterparts in certain fields.

Dr. Huang believes that to be an enterprise, we should insist on something, and do something but not everything. As brand owners, we must have a clear market product positioning. On the one hand, we find room for cost reduction from product research and development and technology research and development and provide customers with good and cheap products; on the other hand, we cannot voluntarily give up performance and quality requirements for price competition. Competition always exists, and competition is also the driving force for corporate progress, but companies should pay more attention to the incremental needs of downstream customers. Dr. Huang revealed that in the past few years, GZTECH's annual R&D investment accounted for no less than 10% of its revenue. High-intensity investment has guaranteed the core competitiveness of the company. Continuous high-intensity investment is a marathon. As a young company, GZTECH has the ideal ambition and value concept of "Illuminate all things, be sincere and far-reaching". Dr. Huang hopes that people in the laser industry will work together to make laser equipment a fundamental productivity tool for intelligent manufacturing.

By continuing to use the site you agree to our privacy policy Terms and Conditions.