Copyright © 2022 Wuhan Guangzhi Technology Co., Ltd All rights reserved.Site MapDesigned by

Welcome:GZTECH

Welcome:GZTECH

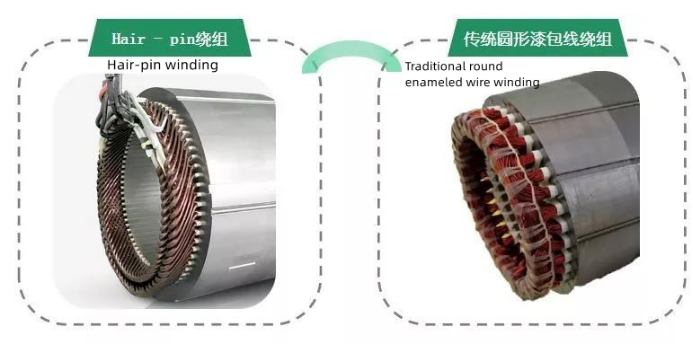

As we all know, the core of the new energy vehicle drive system is the drive motor. In order to improve the power and economy of the vehicle within a limited volume, the drive motor is also constantly developing in the direction of high power density and high motor efficiency. The application of flat enameled wire can significantly increase the effective copper area and reduce copper consumption compared with the traditional round enameled wire winding. And the copper wire arrangement in the slot is more regular and the slot full rate is higher. The application of flat enameled wire can significantly improve the efficiency and power density of the drive motor.

Enameled wire,And the copper wire arrangement in the slot is more regular and the slot full rate is higher. The application of flat enameled wire can significantly improve the efficiency and power density of the drive motor. also known as magnet wire, is composed of conductor and insulating layer. It is one of the main supporting raw materials in the fields of electricity, motors, electrical appliances, home appliances, electronics, communications, transportation, power grids, aerospace and other fields.

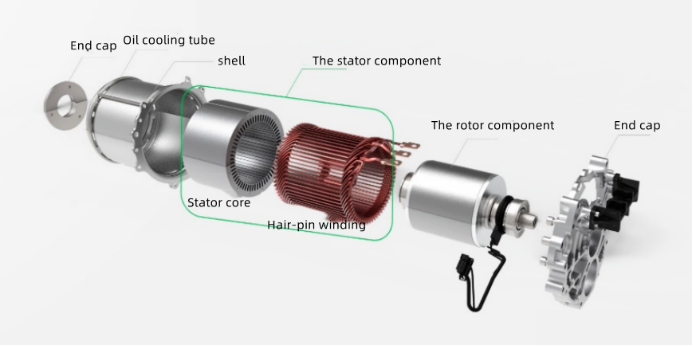

The obvious trend of automotive intelligence and electrification has significantly increased the demand for enameled wire applications. Among them, the demand for flat enameled wire has greatly increased due to the technical outlet ushered in by the Hair-pin hairpin motor (also called flat copper wire winding motor). Hair-pin motors have become the development direction of passenger car drive motors resolutely pursued in the industry. Top domestic motor suppliers have also begun to invest in the construction of more advanced second-generation hair-pin high-automation production lines.

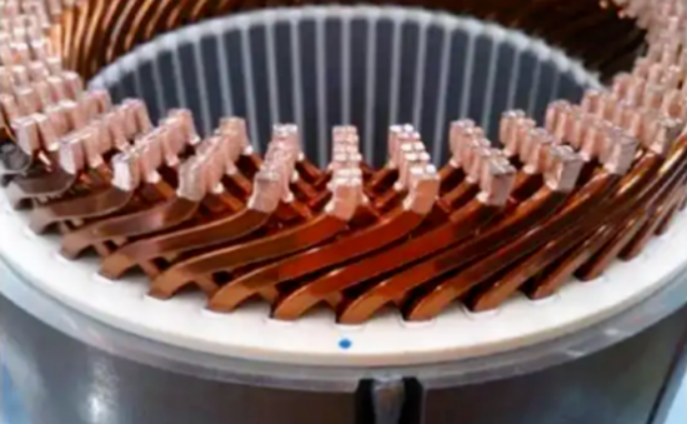

The hair-pin winding manufacturing process is very complex. It is necessary to peel the end of the flat enameled wire first, then make it into the shape of a hairpin, insert it into the slot of the stator core, and then perform end twisting and welding. The quality of enameled wire peeling determines the effect of end welding in the later stage, which directly affects the performance of the motor.

Traditional enameled wire peeling methods include chemical paint removal, flame paint removal, mechanical paint removal, etc., which have problems such as wire damage, unclean removal, and environmental pollution. Laser paint removal uses a high-energy-density laser to irradiate the specified enameled wire position, and the insulating layer on the surface absorbs the energy and vaporizes, exposing the copper. Laser processing has the advantages of no consumables, non-contact, flexible operation, etc., and it is also easy to realize automation. CO₂ laser was first used for enameled wire cleaning, but generally, it cannot completely remove the insulating layer and requires secondary processing. Q-switched lasers are difficult to meet higher and higher efficiency requirements due to low power.

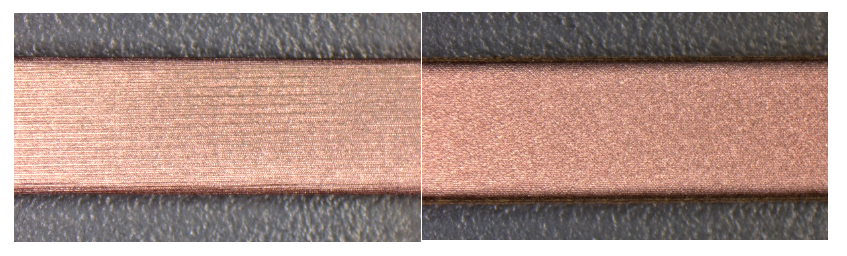

GZTECH is a high-tech company specializing in MOPA pulsed fiber lasers. It is the first to break through single-mode high-power MOPA pulsed fiber laser technology in China and achieve mass production of 500W high-power single-mode pulsed fiber lasers. The engineers conducted the flat enameled wire removal test with the company's mass-produced YFPN-200-GM, YFPN-300-GM and YFPN-500-GM single-mode high-power MOPA pulsed lasers, aiming to obtain the fastest efficiency and best results to provide the best enameled wire cleaning solutions for customers. After testing, it was found that for the same power laser, the shorter the focal length of the field lens, the higher the efficiency, but the rougher the copper wire shading. When the power is low, the insulating layer of the field lens with a large focal length may not be cleaned cleanly. Using a large field lens with high power can obtain a larger depth of focus and more delicate shading, and the efficiency can still be guaranteed.

300W surface after cleaned (F160 left, F210 right)

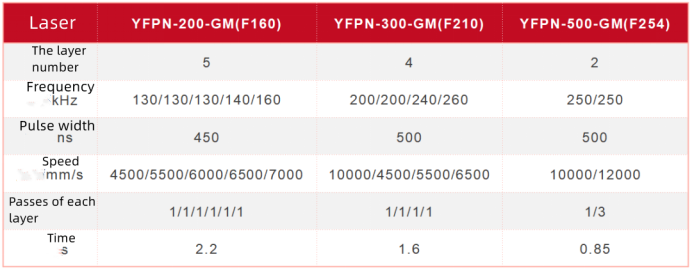

We recommend 200W with F160, 300W with F210, and 500W with F254 field lens to get the best effect and efficiency, test according to the size of 30*4.5mm2, and the parameters are as follows.

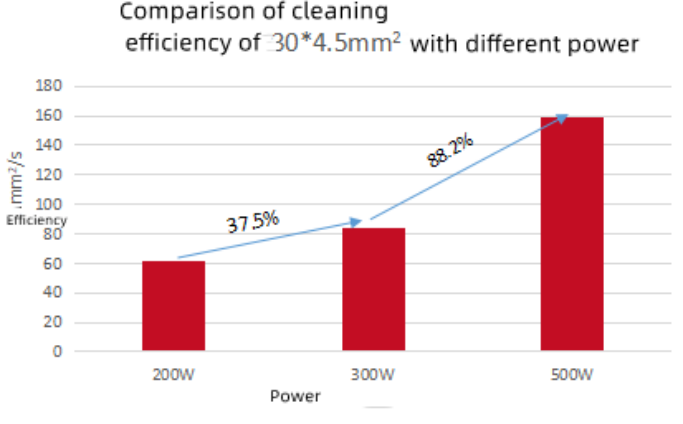

According to the above parameters, the higher the power, the simpler the layer parameters, the faster the efficiency, and the larger the focal length of the field lens that can be selected, but the higher the requirements for the galvanometer. In terms of efficiency, 300W can increase 37.5% compared to 200W, while 500W can increase 159% compared to 200W and 88.2% compared to 300W.

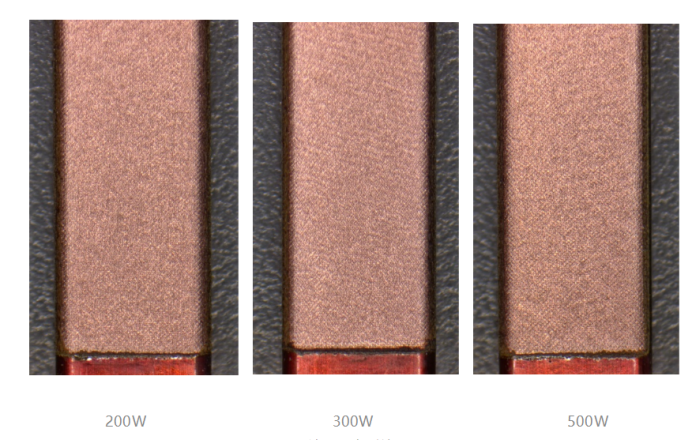

Surface effect after cleaning

In effect, YFPN-200-GM, YFPN-300-GM and YFPN-500-GM can remove the insulating layer cleanly without residue, and the shading is fine. Among them, YFPN-500-GM adopts water cooling design, which has good stability, high single pulse energy (2mJ), good beam quality (≤1.8), 17 kinds of pulse widths (20-500ns), and continuous mode and large adjustment range (1-4000kHz), etc. In the control, it can also adjust the first pulse, switch parameters online in real time, and it has the function of network port to realize multi-machine joint debugging.

With the maturity of domestic high-power MOPA single-mode laser technology, as the first laser technology company in China to achieve mass production and mass delivery of 500W single-mode MOPA, GZTECH has achieved complete import substitution for high-power MOPA lasers, reducing costs for customers and increasing the efficiency of the industry. The application of high-power MOPA laser cleaning technology in flat motors is a vivid case. In the future, GZTECH will continue to develop more and more meaningful advanced laser applications.

By continuing to use the site you agree to our privacy policy Terms and Conditions.