Copyright © 2022 Wuhan Guangzhi Technology Co., Ltd All rights reserved.Site MapDesigned by

Welcome:GZTECH

Welcome:GZTECH

In the process of the TWh era, battery companies have an increasing demand for production line capacity, yield, and product quality, presenting new challenges to lithium battery equipment and key components.

Lasers are the core accessories of lithium battery equipment, and laser companies are constantly forging their own competitiveness, providing innovative support for lithium battery intelligent manufacturing with layer-by-layer iterative laser products and automation technologies, and enabling high-quality lithium battery manufacturing.

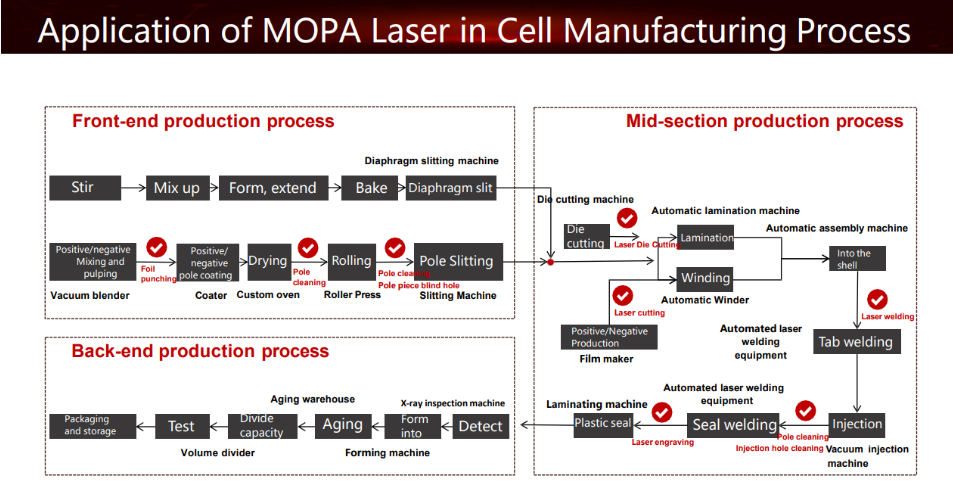

With the advantages of no consumables, no pollution, no contact stress, high processing quality and precision, and easy automation of equipment, laser processing has ushered in large-scale applications in core processes such as front-end production of power batteries, mid-stage welding, and rear-end module pack packaging, involving process steps including cutting, welding, cleaning and coding.

Dr. Zhihua Huang introduced that the MOPA laser adopts the structure of main oscillator plus power amplifier. Compared with traditional lasers, its parameter adjustment dimension is higher and the range is wider, and for different application scenarios of different materials, MOPA is more adaptable and has a larger process range.

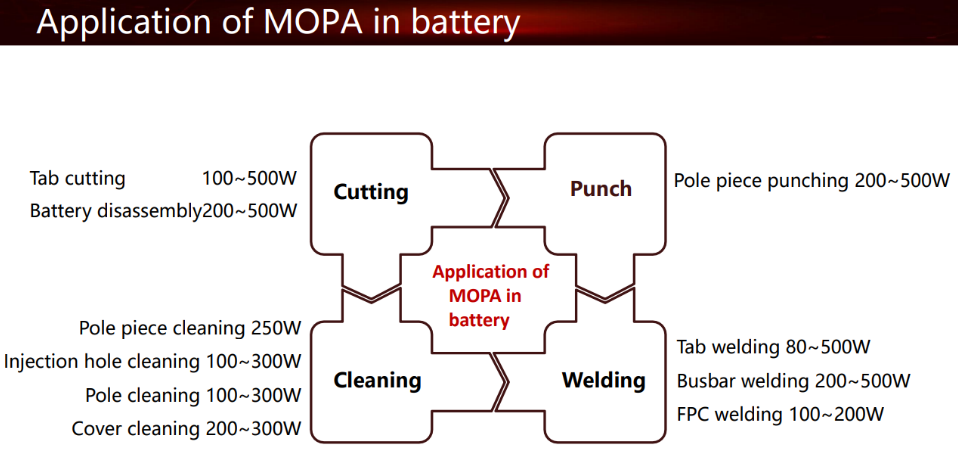

At present, the application of MOPA lasers in the cell manufacturing process has covered the core process such as front-end production, mid-stage welding, and back-end module pack packaging, mainly involving cutting, welding, cleaning and coding, etc. In the future, it will also play an important role in battery recycling and disassembly. Focusing on the application of MOPA lasers in lithium batteries, Dr. Zhihua Huang shared the exploration and application of optical technology of GZTECH in this field.

The pole piece material is in the shape of a long strip, and the cutting material involves multiple areas involving the foil, ceramic layer, and coating layer, so different laser parameters need to be used in different areas. At present, high-power MOPA lasers are the most widely used in the field of high-speed tab cutting, and the delivery scale is large.

The positive electrode material is currently a more difficult type of cutting material, because the melting point of the aluminum foil is very low, but the melting point of the coating layer is high, and the cutting process is very easy to form burrs.

In the process verification, GZTECH found that the main factor affecting the efficiency and effect of aluminum foil cutting is the laser power, but if the power is too high and the pulse energy is too high, the plane and end face burrs will exceed the standard. This type of material is cut with low energy and high frequency (similar to continuous mode), which can achieve better process results. Its 250W/500W both have as low as 10ns short pulse width, high peak value, and frequency up to 4000kHz, which are very suitable for positive electrode material cutting.

GZTECH MOPA pulse laser pulse width can be as low as 10ns. The increase of 300W/500W center frequency can effectively improve the cutting speed, and there is no plane burr and end-face burr.

The main difficulty lies in the cleaning of the positive electrode piece. GZTECH explored the cleaning efficiency effect of different coating thicknesses of 250W and found that the removal efficiency was the highest when the coating thickness was 55um. The removal efficiency was the highest when the spot overlap was about 50%.

Removal of electrolytes has certain requirements for depth, and large field mirrors are used to prevent sparks from flying or cells with large amplitude, which puts higher requirements on beam quality, laser stability, generated beats, response time, etc.

The use of laser cleaning blue film can greatly improve cleaning efficiency and product quality, and reduce labor costs. Comparing the 500W single-mode and multi-mode laser tests, it is found that the 500W multi-mode removes cleanly, and the substrate is basically free of damage, while single mode will damage the substrate to a great extent.

GZTECH has developed a customized machine with supporting process verification. The single pulse energy is increased by 2mJ high-power pulsed laser to achieve a better punching effect.

The new MOPA laser of GZTECH can realize a non-destructive black code on a white background on a pure aluminum shell, with high contrast and easy identification, which greatly simplifies the error rate of visual identification on the production line.

Dr. Zhihua Huang said that MOPA lasers are easy to realize welding of various materials due to the wide selection range of pulse width, large repetition frequency range, arbitrary switching between pulse and continuous modes, and good beam quality. With less heat input, small back marks, and high welding strength, it also has a good effect in the field of power battery welding.

As in the past, low-power MOPA was only suitable for welding 0.2mm thickness of the thin film. After GZTECH increased the power to 500W or even 1000W, the thickness of the materials that could be welded was greatly expanded, enabling a single station to be compatible with welding processes of multiple materials at the same time, reducing the complexity of the customer's production line layout and production costs.

In module recycling and cell separation, when the existing continuous laser is cutting the busbar or the battery case, the large heat input will inevitably cause damage or even breakdown of the underlying material, which may easily cause the electrolyte to explode. The MOPA laser can effectively control the input heat and vaporize the material multiple times through a single layer to realize the safe disassembly of the battery. GZTECH 500W MOPA has a very high disassembly efficiency.

In the view of Dr. Zhihua Huang, MOPA laser technology will iterate and develop in the dimensions of power improvement, intelligent control, multi-parameters, and wide application

As a rising star in the laser field, GZTECH was established in May 2018. It is a high-tech laser R&D and production enterprise positioned as a leading supplier of advanced industrial laser products for precision manufacturing, specializing in the development and production of high-power nanosecond pulse and ultrafast pulse fiber lasers, and providing laser-related custom product development services.

At present, GZTECH can provide a full range of adjustable nanosecond pulse MOPA lasers from 20W to 1000W. By supporting many mainstream laser equipment manufacturers in China, it has deeply involved in the new energy field, such as the high-speed production of pole pieces, pole ear cutting, pole piece cleaning, injection hole cleaning, erasable black code etching and other customized services for new processes, etc.

GZTECH will continue to strengthen product research and development, deep cooperation with equipment manufacturers and battery manufacturers, and continue to improve product performance and launch new products to meet the demands of power battery companies to improve quality and reduce costs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.